Conveyor Belts Solid Woven

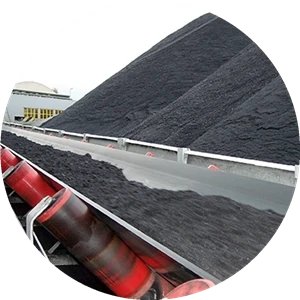

Solid Woven Conveyor Belt

PVG chevron pattern conveyor Belt

Solid Woven Conveyor Belt, uses high strength, low elongation, the high-quality polyester filament in the warp, and high strength, moderate modulus nylon filament in the weft, mainly used for conveying in underground coal mines, which can be divided into PVC type and PVG type.

- For the PVC type conveyor belt, both the top and bottom cover is PVC (Poly Vinyl Chloride) rubber cover, with a coating rubber thickness of ≥0.8mm and at a slope angle of <16°;

- For the PVG type conveyor belt, both the top and bottom cover are Nitrile rubber blends PVC (Poly Vinyl Chloride), with a coating rubber thickness of 1.5~4.5mm, and at a enhanced slope angle of <20°.

The antistatic performance far exceeds the national standard value of MT914-2008.

The PVG pattern herringbone conveyor belt is an enhance inclined angle conveyor belt composed of a pattern-shaped cover rubber on the working surface.

Feature Characteristics of Solid Woven conveyor belts:

- Anti-static, Chemical and moisture resistant, flame resistance

- High strength, low elongation, shock resistant, anti-tear, good trough-ability

- Extreme adhesion and abrasion and impact resistance

Technical of Solid Woven conveyor belts:

| Incline degree | PVC incline <16°; PVG incline <20°; |

| Type of Fabric | PVC / PVG |

| Tension Strength | Warp: 680 to 1400 N/mm; Weft: 265 to 360 N/mm; |

| Rubber Cover Thickness | PVC: 21.0mm (0.83″); PVG: 1.5mm (0.059″) to 4.5mm (0.18″); |

| Colour | Black |

| Edge | Cut Edge / Moulded Edge |

| Splicing Method | Hot / Cold / Mechanical |

| Standard Packing | Wrapping in HDPE sheets with Strapping. (Wooden Pallet / Metal Frame is available) |

| Belt Identification Number | A unique BIN (Belt Identification Number) At Every 10 Meters(33′) |